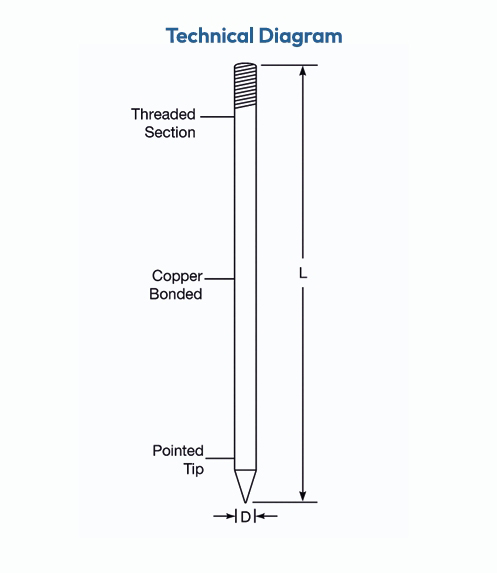

Manufactured from high tensile low carbon steel by molecularly bonding 99.9% pure electrolytic copper, these ground rods conform to BS 436O grade 43A.

Nikkon Ferro uses a unique manufacturing process, which includes drawing the steel rod to size before the copper bonding process begins. This results in a straighter, harder steel core, making installation

easier. We use a carefully designed electro-plating process over the steel core thot results in a permanent molecular bond that provides decades of reliable performance.

Each rod is treated with Benzol Triozole derivatives to prevent oxidation of copper bonding.

Our state-of-the-art ISO registered manufacturing facility provides a consistent, high-quality finished product that is used in millions of installations around the world.

The threads ore formed by a roll threading process which ensures strength and maintains the molecularly bonded copper along the full length of the threads. The rods con be deep driven manually or by using a power hammer.

Grounding systems in general (power generation, transmission and distribution systems), grounding grids, residential, building and industrial grounding, substations grounding and telecommunications networks.

Product Variation

| NFPL Part Number | Dimensions Diameter(inch) × Length(ft) |

Diameter (mm)# | Weight per piece (kg/Lbs) |

Micron Coating* | Packing Bundle Size |

|---|---|---|---|---|---|

| CE512 | 1/2” × 5’ | 12.70 | 1.53 kg / 3.37 lbs | 254 | 10/100 |

| CE612 | 1/2” × 6’ | 12.70 | 1.84 kg / 4.05 lbs | 254 | 10/100 |

| CE812 (UL) | 1/2” × 8’ | 12.70 | 2.45 kg / 5.39 lbs | 254 | 10/100 |

| CE1012 (UL) | 1/2” × 10’ | 12.70 | 3.06 kg / 6.73 lbs | 254 | 10/100 |

| CE558 | 5/8” × 5’ | 14.30 | 1.91 kg / 4.20 lbs | 254 | 10/100 |

| CE658 | 5/8” × 6’ | 14.30 | 2.3 kg / 5.06 lbs | 254 | 10/100 |

| CE858 (UL) | 5/8” × 8’ | 14.30 | 3.06 kg / 6.73 lbs | 254 | 10/100 |

| CE1058 (UL) | 5/8” × 10’ | 14.30 | 3.83 kg / 8.43 lbs | 254 | 10/100 |

| CE534 | 3/4” × 5’ | 17.20 | 2.82 kg / 6.20 lbs | 254 | 5/50 |

| CE634 | 3/4” × 6’ | 17.20 | 3.38 kg / 7.44 lbs | 254 | 5/50 |

| CE834 (UL) | 3/4” × 8’ | 17.20 | 4.51 kg / 9.92 lbs | 254 | 5/50 |

| CE1034 (UL) | 3/4” × 10’ | 17.20 | 5.64 kg / 12.41 lbs | 254 | 5/50 |

| CE588 | 1” × 5’ | 23.20 | 5.09 kg / 11.20 lbs | 254 | 5/25 |

| CE688 | 1” × 6’ | 23.20 | 6.11 kg / 13.44 lbs | 254 | 5/25 |

| CE888 (UL) | 1” × 8’ | 23.20 | 8.14 kg / 17.91 lbs | 254 | 5/25 |

| CE1088 (UL) | 1” × 10’ | 23.20 | 10.18 kg / 22.40 lbs | 254 | 5/25 |

# Diameter variation is +/- 0.1mm from indicated levels in the table.

* Micron coating can be customized per requirement. Available as required for 25 micron, 125 micron, or 330 microns.

* UL Listing only available on rods with minimum 254 micron coating and length greater than 2,400mm / 8ft

* 1/2” diameter rods have 12/13 UNC threading as per customer requirement

* 5/8” diameter rods have 11 UNC threading

* 3/4” diameter rods have 10 UNC threading

©2025 Nikkon Ferro Private Limited. All Rights Reserved | Designed and Developed by: Technocrats India.