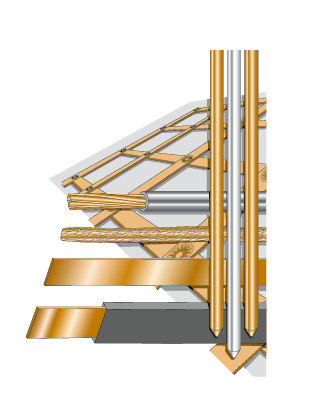

The ground electrode is a critical component of the grounding system. Many different types of electrodes are available, some “natural” and some “made”.

The natural types include metal underground water pipe, the metal frame of a building (if effectively grounded), a copper wire or reinforcing bar in a concrete foundation or underground structures or systems. consideration should be given to bonding of natural earths to ensure electrical continuity with a facility's other “earths”.

“Made” electrodes are specifically installed to improve the system grounding or earthing. These earth electrodes must ideally penetrate into the moisture level below the ground level to reduce resistance. They must also consist of metal conductors (or a combination of metal conductor types),

which do not corrode excessively for the period of time they are expected to serve. Made electrodes include rods or pipes driven into the earth, metallic plates buried in the earth or a copper wire ring encircling the structure. Underground gas piping or aluminum electrodes are NOT permitted for use as ground electrodes.

Ground rods are often selected on the basis of their resistance to corrosion. The other major factor is cost.

All too often, the cost of a product is seen as the initial up front price, but the real cost is determined by the serviceable life of the ground rod.

Galvanized steel rods are one of the cheapest electrodes available. However, they are not the most cost elective since they have a relatively short service life.

Solid copper and stainless steel rods have a long service life. However, they are considerably more expensive than galvanized steel rods. In addition to this, solid copper rods are not suited to deep driving or even driving short lengths into hard ground, without bending.

The photo shows two ground rods subjected to the same pressure load test. Copper-bonded ground rod, shown on the left, will bend without tears, cracks or folds, to the outer sheath. The inferior copper clad rod shown on the right, has developed cracks and creases to the outer sheath,

which will significantly reduce its serviceable life and put the integrity of the entire electrode at risk.

©2025 Nikkon Ferro Private Limited. All Rights Reserved | Designed and Developed by: Technocrats India.